Kualitas luhur CNC Shearing Mesin

1. Sakabéh pigura mesin diolah ku Jérman SHW puseur processing pentahedron dina hiji waktu.

4. Sudut shearing bisa gampang disaluyukeun ngaliwatan programming pikeun nyingkahan deformasi workpiece disababkeun ku motong.

5. Panjang stroke beam luhur bisa otomatis disaluyukeun ngawujudkeun motong saum sareng tepat workpiece pondok tur leutik guna ngaronjatkeun efisiensi gawé.

6. Sistim CNC otomatis bakal nyaluyukeun gap wilah nurutkeun ketebalan lambar béda jeung bahan pikeun ngaronjatkeun kualitas motong.

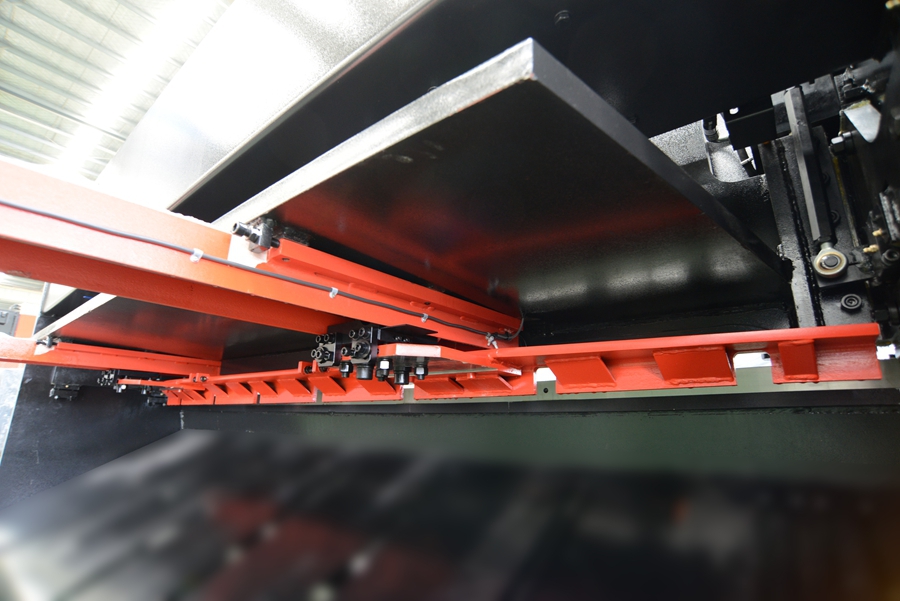

7. Opat-sisi shearing sabeulah diadopsi pikeun ngaronjatkeun kahirupan layanan sabeulah nu leuwih hade tinimbang nu geser ayun.

8, Desain anyar backgauge, struktur stabil, ningkatkeun résistansi ngagem, crashworthiness pisan

2. Ngadopsi sistem CNC Delem DAC360:

● persis ngadalikeun backgauge

● persis ngadalikeun shearing stroke

● persis ngadalikeun sudut shearing

● persis ngadalikeun wilah clearance

● persis ngadalikeun jumlah jobs.

3. Ngadopsi sistem hidrolik terpadu BOSCH Jerman:

● pikeun simplify pipa nu

●pikeun ngahindarkeun leakage minyak

● pikeun ngaronjatkeun stabilitas gawé

● mun beautify penampilan mesin

1. dipaké pikeun kontrol otomatis tina mesin shearing kalawan pinuh-fungsi hareup-dahar atanapi backgauge

2. adopts tampilan LCD harti luhur, tipe menu programming;

3. sudut shearing, gap sabeulah, shearing stroke otomatis itungan jeung kontrol;

4. konstruksi modular, harti fléksibel atawa manjangkeun X1-X2 nyingkronkeun kontrol dahar jeung kontrol sumbu Z bantu;

5. adopts posisi mutlak tur programming posisi relatif;

6. pilarian otomatis titik rujukan, sarta memori kaluar-posisi bisa diatur;

7. desain kabayang leungeun unik sangkan adjustment mesin merenah;

8. RS232 panganteur serial;

9. kaluaran tina multi-diartikeun pamaké sinyal bantu;

10. program diagnosis diri;

11. panyimpenan internal tina 100 garis program;

12. 4.7 inci LCD harti luhur;

13. fungsi cacah program;

14. Pilihan Unit ukuran antara sistem métrik jeung sistem Inggris.

| No. | Barang | Qty. | Nyarios |

| 1 | Payil Mesin | Hiji set | |

| 2 | Hex stop kontak Spanner | Hiji set | |

| 3 | Grease Gun | Hiji no. | |

| 4 | Grounding Bolt | Hiji set | |

| 5 | Nyaluyukeun Bolt | Hiji set | |

| 6 | Kadali suku | Hiji no. |

1. Sumber hawa: pastikeun tekanan gas disadiakeun pikeun mesin kudu leuwih ti 0,6 Mpa, aliran gas kudu leuwih ti 0,3 m3 / mnt.

2. minyak hidrolik: diimpor VG46 # minyak hidrolik anti maké. Massa minyak anu diperyogikeun diatur di handap:

| Modél Mesin | Beurat Minyak (L) |

| VR6, runtuyan VR8 | 230 |

| runtuyan VRZ | 690 |

| runtuyan VR10 | 370 |

| VR13 * 3200 | 460 |

| VR13 * 6200 | 800 |

3.Power: 380V,50HZ, tegangan turun naek ± 10%

4. Suhu lingkungan: 0°C - +40°C

5. Kelembaban lingkungan: kalembaban relatif 20-80% RH (non-condensing)

6. Jauhkeun tina sumber geter anu kuat sareng gangguan éléktromagnétik

7. Lebu saeutik, euweuh gas ngabahayakeun atawa corrosive

8. Nyiapkeun yayasan nurutkeun gambar yayasan

9. Pilih tanaga relatif jeung kasang tukang atikan tangtu pikeun susunan jangka panjang salaku operator mesin.

Mesin Gunting CNC; Gunting Guillotine Hidrolik; Mesin Gunting; Gunting cnc

2500

| Katerangan | Unit | 6*2500 | |

| Ketebalan Shearing (mm) | Hampang Steel 450Mpa | mm | 0.5-6 |

| Stainless Steel 600Mpa | 0.5-4 | ||

| Aluminium 300Mpa | 0.5-8 | ||

| Shearing Panjang | mm | 2500 | |

| Sudut Shearing | ° | 0,5 ° ~ 2 ° | |

| Balik- gauge | Stroke mm | mm | 5~1000 |

| Laju mm/s | mm/s | ≤250 | |

| Akurasi mm | mm | ± 0,1 | |

| Servo Motor Power KW | KW | 1 | |

| Stroke Times | hpm | 25-36 | |

| Kapasitas Silinder (L) | L | 230 | |

| No tina Clamping | henteu. | 12 | |

| Daya Motor Utama (KW) | KW | 11 | |

| Sistim CNC | Holland Delem DAC360 Sistim CNC ngadalikeun sudut shearing, sela wilah, sarta shearing stroke | ||

| No. sareng panjang panangan dukungan (mm) | mm | 3*1400 | |

| Outline Dimensi | Panjangna (mm) | mm | 3110 |

| Lebar (mm) | mm | 3000 | |

| Jangkungna (mm) | mm | 1705 | |

3000/3200

| Katerangan | Unit | 6*3000 | 8*3000 | 10*3000 | 13*3200 | 16*3200 | ||||

| Ketebalan Shearing (mm) | Hampang Steel 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||

| Stainless Steel 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||

| Aluminium 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||

| Shearing Panjang | mm | 3070 | 3070 | 3070 | 3200 | 3200 | ||||

| Sudut Shearing | ° | 0,5 ° -2 ° | 0,5 ° -2 ° | 0,5 ° -2 ° | 0,5 ° -2 ° | 0,5 ° -2 ° | ||||

| Balik- gauge | Stroke mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||

| Laju mm/s | mm/s | ≤250 | ≤250 | ≤250 | 200 | 200 | ||||

| Akurasi mm | mm | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | ||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||

| Stroke Times | hpm | 22-35 | 16-34 | 15-32 | 10-15 | 9-16 | ||||

| Kapasitas Silinder (L) | L | 230 | 230 | 370 | 460 | 460 | ||||

| No tina Clamping | henteu. | 14 | 14 | 14 | 15 | 15 | ||||

| Daya Motor Utama (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||

| Sistim CNC | Holland Delem DAC360 Sistim CNC ngadalikeun sudut shearing, sela wilah, sarta shearing stroke | |||||||||

| No. sareng panjang panangan dukungan (mm) | mm | 3*1400 | 3*1400 | 3*1400 | 3*1000 | 3*1000 | ||||

| Outline Dimensi | Panjangna (mm) | mm | 3610 | 3640 | 3720 | 4075 | 4300 | |||

| Lebar (mm) | mm | 3000 | 3000 | 3040 | 2752 | 3000 | ||||

| Jangkungna (mm) | mm | 1705 | 1755 | 1880 | 2432 | 2850 | ||||

4000

| Katerangan | Unit | 6*4000 | 8*4000 | 10*4000 | 13*4000 | 16*4000 | ||||||

| Ketebalan Shearing (mm) | Hampang Steel 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||||

| Stainless Steel 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||||

| Aluminium 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||||

| Shearing Panjang | mm | 4070 | 4070 | 4070 | 4000 | 4000 | ||||||

| Sudut Shearing | ° | 0,5 ° ~ 2 ° | 0,5 ° ~ 2 ° | 0,5 ° ~ 2 ° | 0,5 ° ~ 2,5 ° | 0,5 ° ~ 2,5 ° | ||||||

| Balik- gauge | Stroke mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||||

| Laju mm/s | mm/s | ≤250 | ≤250 | ≤250 | ≤200 | ≤200 | ||||||

| Akurasi mm | mm | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | ||||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||||

| Stroke Times | hpm | 16~34 | 14~32 | 12~32 | 10-15 | 8-15 | ||||||

| Kapasitas Silinder (L) | L | 230 | 230 | 370 | 460 | 460 | ||||||

| No tina Clamping | henteu. | 18 | 18 | 18 | 19 | 19 | ||||||

| Daya Motor Utama (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||||

| Sistim CNC | Holland Delem DAC360 Sistim CNC ngadalikeun sudut shearing, sela wilah, sarta shearing stroke | |||||||||||

| No. sareng panjang panangan dukungan (mm) | mm | 4*1400 | 4*1400 | 4*1400 | 4*1000 | 4*1000 | ||||||

| Outline Dimensi | Panjangna (mm) | mm | 4610 | 4640 | 4720 | 4970 | 5300 | |||||

| Lebar (mm) | mm | 3000 | 3000 | 3040 | 2760 | 3000 | ||||||

| Jangkungna (mm) | mm | 1705 | 1705 | 1880 | 2562 | 2850 | ||||||

6000/6200

| Katerangan | Unit | 6*6000 | 8*6000 | 13*6200 | 16*6000 | 16*6200 | |||

| Ketebalan Shearing (mm) | Hampang Steel 450Mpa | mm | 0.5~6 | 0.8~8 | 1-13 | 1-16 | 1-16 | ||

| Stainless Steel 600Mpa | 0.5~4 | 0.8~5 | 1-8 | 1-10 | 1-10 | ||||

| Aluminium 300Mpa | 0.5~8 | 0.8~10 | 1-18 | 1-20 | 1-20 | ||||

| Shearing Panjang | mm | 6140 | 6140 | 6200 | 6000 | 6200 | |||

| Sudut Shearing | ° | 0,5˚-2˚ | 0,5˚-2,5˚ | 0,5˚-2,5˚ | 0,5˚-2,5˚ | 0,5˚-2˚ | |||

| Balik- gauge | Stroke mm | mm | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 | ||

| Laju mm/s | mm/s | 200 | 200 | 200 | 200 | 200 | |||

| Akurasi mm | mm | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | |||

| Servo Motor Power KW | KW | 1.0 | 1.0 | 1.0 | 1.5 | 2.0 | |||

| Stroke Times | hpm | 12~20 | 12~20 | 6-10 | 5-9 | 5-9 | |||

| Kapasitas Silinder (L) | L | 690 | 690 | 800 | 800 | 800 | |||

| No tina Clamping | henteu. | 29 | 29 | 27 | 27 | 27 | |||

| Daya Motor Utama (KW) | KW | 11 | 15 | 30 | 37 | 37 | |||

| Sistim CNC | Holland Delem DAC360 Sistim CNC ngadalikeun sudut shearing, sela wilah, sarta shearing stroke | ||||||||

| No. sareng panjang panangan dukungan (mm) | mm | 6*1000 | 6*1000 | 6*1000 | 6*1000 | 6*1000 | |||

| Outline Dimensi | Panjangna (mm) | mm | 7055 | 7115 | 7220 | 7300 | 7500 | ||

| Lebar (mm) | mm | 2686 | 2690 | 2945 | 3000 | 3000 | |||

| Jangkungna (mm) | mm | 2495 | 2680 | 2850 | 2850 | 2850 | |||

runtuyan VR (Z):

| No. | Ngaran | Modél | merek |

| 1 | Sistim CNC | Sistim CNC DAC360 | Holland Delem |

| 2 | Motor Servo | EMJ-10APB22 | Éstun |

| 3 | Supir Servo | RONET-E-10A-AMA | Éstun |

| 4 | Sistim hidrolik | Éléktro-servo klep hidrolik set | Jérman Bosch-Rexroth |

| a. katup tekanan proporsional | |||

| b. katup kartrij | |||

| c. klep pamilih éléktromagnétik | |||

| d. katup tekanan overlay | |||

| e. kontrol hidrolik klep hiji arah | |||

| f. katup throttle | |||

| e. klep hiji arah jsb. | |||

| 5 | Panungtun linier | HSR25A-1240L | THK atanapi PMI |

| 6 | Ballscrew | 25/20-1400mm | THK atanapi PMI |

| 7 | Pompa oli | IPH-5B-50-11atawa PGH4-3X/050-E11VU2 | Jepang NACHI pompa atawa Jerman Rexroth |

| 8 | Set lengkep cincin sealing dina silinder minyak | AS PARKER | AS PARKER |

| 9 | Set lengkep pipa tekanan tinggi | 1.F372C91C161608-1200mm | USA PARKER, EO-2 pipe gabungan atawa Jerman VOSS pipe gabungan |

| 2.F372C91C161608-1950mm(2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm(3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Atawa F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF jsb. | |||

| 10 | Gandeng | R38 25.385/42 jsb. | Jérman KTR |

| 11 | Kontaktor AC | LC1-D38B7C, LC1-D25B7Cetc. | Schneider |

| 12 | Pindah deukeut | TP-SM5P2 jsb. | TEND |

| 13 | Terminal kalungguhan | TB2.5B TB16ICH jsb. | Phoenix |

| 14 | Tombol | XB2-BVB3LC jsb. | Schneider |

| 15 | Ngalukis | KAILEDI |

runtuyan VR (Z):

| No. | Ngaran | Modél | merek |

| 1 | Sistim CNC | Sistim CNC DAC360 | Holland Delem |

| 2 | Motor Servo | EMJ-10APB22 | Éstun |

| 3 | Supir Servo | RONET-E-10A-AMA | Éstun |

| 4 | Sistim hidrolik | Éléktro-servo klep hidrolik set | Jérman Bosch-Rexroth |

| a. katup tekanan proporsional | |||

| b. katup kartrij | |||

| c. klep pamilih éléktromagnétik | |||

| d. katup tekanan overlay | |||

| e. kontrol hidrolik klep hiji arah | |||

| f. katup throttle | |||

| e. klep hiji arah jsb. | |||

| 5 | Panungtun linier | HSR25A-1240L | THK atanapi PMI |

| 6 | Ballscrew | 25/20-1400mm | THK atanapi PMI |

| 7 | Pompa oli | IPH-5B-50-11atawa PGH4-3X/050-E11VU2 | Jepang NACHI pompa atawa Jerman Rexroth |

| 8 | Set lengkep cincin sealing dina silinder minyak | AS PARKER | AS PARKER |

| 9 | Set lengkep pipa tekanan tinggi | 1.F372C91C161608-1200mm | USA PARKER, EO-2 pipe gabungan atawa Jerman VOSS pipe gabungan |

| 2.F372C91C161608-1950mm(2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm(3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Atawa F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF jsb. | |||

| 10 | Gandeng | R38 25.385/42 jsb. | Jérman KTR |

| 11 | Kontaktor AC | LC1-D38B7C, LC1-D25B7Cetc. | Schneider |

| 12 | Pindah deukeut | TP-SM5P2 jsb. | TEND |

| 13 | Terminal kalungguhan | TB2.5B TB16ICH jsb. | Phoenix |

| 14 | Tombol | XB2-BVB3LC jsb. | Schneider |

| 15 | Ngalukis | KAILEDI |